Go back

Go back

August 5, 2022 The Boeing 737 MAX 8 aircraft arrived from Seattle, USA (with Belavia painting) to perform painting work at the base of Uzbekistan Airways technics LLC. The owner of the aircraft is the airline "SCAT", the Republic of Kazakhstan, which for many years has been the largest air carrier of Kazakhstani passengers and a long-time partner of OOO "UAT".

Boeing 737 MAX 8 is a narrow—body passenger aircraft of the fourth generation of Boeing 737 models. Its main difference is the more powerful CFM International LEAP-1B engine. The manufacturer of the aircraft is the American corporation The Boeing Company.

Painting an aircraft takes an average of 10 days. The duration of these works depends on the complexity of the livery and the type of aircraft.

Currently, OOO "UAT" uses several painting systems. In this case, for the Boeing 737 MAX 8 aircraft, the painting will be performed using the Intermediate Coat Paint System Base Coat/Clear Coat (base + varnish), using Akzo Nobel paint coatings.

At the first stage, the aircraft is cleaned from the paint to the base using a special chemical composition (Paint Remover). Then the surface is washed, degreased, primed, then drying takes place. The soils used are different, differing in characteristics.

Those parts that are not subject to processing at this stage are protected. Then, after checking the quality of the primer application, the surfaces are degreased again and a base coat of paint is applied. Only after a couple of hours, after drying, it will be possible to apply the next layer of paint.

The next step is the application of stickers and stencil information. There are dozens, if not hundreds, of them on the plane. In parallel, specialists correct the smallest defects with the help of mini-pistols, work with a brush in the most inaccessible and difficult places, while removing the remnants of insulation.

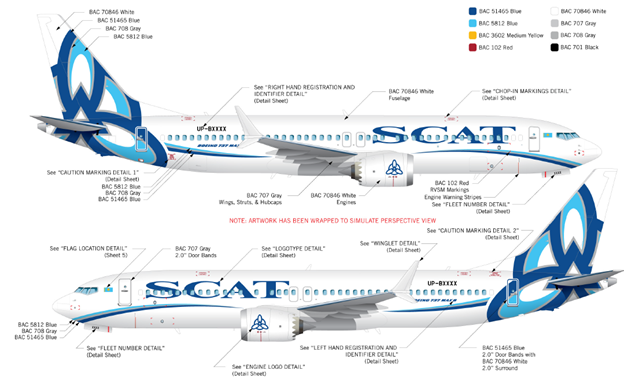

Scheme of livery application and stencil information

After performing these works, the quality of the coating is checked and the thickness is checked by specialized devices. The standard indicator of the thickness of the paint on the plane is up to 300 microns, which is only 3-4 times thicker than a human hair. Therefore, maintaining such a thickness on the huge surface of an aircraft is a complex and time–consuming process. If the layer is thicker, then due to stress and deformations during the flight of the aircraft, the paint may crack.

After passing the coating thickness control, the aircraft will be degreased again and two coats of varnish will be applied with intermediate drying. The varnish creates additional protection and gives shine.

This is how beauty appears, which not only makes the aircraft recognizable and attractive, but also protects it from the adverse effects of the external environment and prolongs its service life.

The approximate consumption of paint and varnish materials for painting one aircraft is 130 – 200 liters.

After the painting work is completed, the Boeing 737 MAX 8 aircraft will be weighed to determine the alignment and handed over to the customer.

OUR WORK ON EARTH IS YOUR CONFIDENCE AND SAFETY IN THE SKY!